Products Description

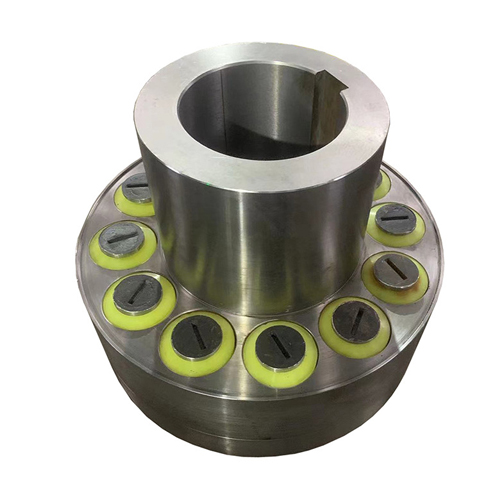

TL TypePin Coupling With Elastic SleeveIt Is A Transmission Component That Combines Rigidity And Elasticity, Belonging To The Category Of Elastic Couplings, And Complies With The GB/T 4323 Standard. Its Structure Consists Of Two Flanged Half Couplings, An Elastic Sleeve (usually Made Of Rubber Or Polyurethane Material), And A Column Pin. The Elastic Sleeve Is Fitted Onto The Column Pin, And Torque Transmission Is Achieved Through The Coordination Of The Column Pin And The Pin Hole Of The Half Coupling.

During Operation, The Power Is Transmitted To The Column Pin Through The Active End Half Coupling, And Then The Torque Is Transmitted To The Driven End Through The Elastic Deformation Of The Elastic Sleeve. At The Same Time, The Compression Deformation Of The Elastic Sleeve Is Used To Compensate For The Axial (≤ 2mm), Radial (≤ 0.15mm), And Angular (≤ 1 °) Offsets Between The Two Shafts, Absorb Vibrations, Buffer Impacts, And Effectively Reduce The Noise And Equipment Wear Of The Transmission System.

This Coupling Has A Wide Range Of Torque Transmission (16~16000N · M), And The Allowable Speed Decreases With The Increase Of The Model (the Minimum Allowable Speed Can Reach 8000r/min, And The Maximum Model Is About 950r/min). It Is Suitable For Transmission Scenarios With Low To Medium Speeds, Frequent Starting, And Slight Impact, Such As The Connection Between Motors And Reducers, Water Pumps, Fans, And Other Equipment. Its Advantages Lie In Its Simple Structure, Easy Installation And Maintenance, Convenient Replacement Of The Elastic Sleeve, And No Need To Disassemble The Half Coupling; The Disadvantage Is That The Elastic Sleeve Is Prone To Aging, And Its Lifespan Is Affected By Temperature (-30 ℃~60 ℃ Is Suitable) And Medium. Long Term Use Requires Regular Inspection Of Its Wear Or Crack Condition.

When Selecting, The Model Should Be Matched According To The Shaft Diameter, Maximum Torque, And Speed. Half Couplings Are Mostly Made Of 45 Steel Or Cast Iron, And The Elastic Sleeve Material Can Be Selected According To The Working Conditions: Rubber Has Good Elasticity But Poor Oil Resistance, Polyurethane Has Strong Wear Resistance And Oil Resistance, Suitable For Environments With Oil Mist. During Installation, It Is Necessary To Ensure The Accuracy Of The Two Axis Alignment To Avoid Premature Failure Of The Elastic Sleeve Due To Unbalanced Load.