Products Description

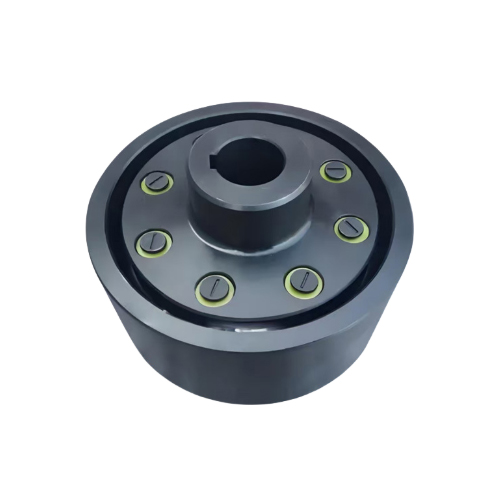

LTZElastic Sleeve Column Pin Coupling With Brake WheelIt Is A Transmission Component That Integrates Braking Function On The Basis Of TL Type, Complies With GB/T 4323 Standard, And Has Dual Characteristics Of Elastic Compensation And Safe Braking. Its Structure Consists Of A Flanged Half Coupling, Brake Wheel, Elastic Sleeve (rubber Or Polyurethane), And Column Pin. The Brake Wheel Is Rigidly Connected To The Half Coupling, And Torque Transmission And Braking Control Are Achieved Through The Cooperation Of The Elastic Sleeve And Column Pin.

During Operation, Power Is Transmitted To The Driven End Through The Active Half Coupling, Column Pin, And Elastic Sleeve. The Deformation Of The Elastic Sleeve Can Compensate For Axial (≤ 2mm), Radial (≤ 0.15mm), And Angular (≤ 1 °) Offsets, Absorbing Vibration Impacts. The Brake Wheels Are Made Of 45 Steel Forging, And Emergency Braking Is Achieved Through The Action Of Friction Plates Or Brake Shoes. The Braking Torque Range Covers 100~16000N · M, With Rapid Response, Suitable For Transmission Systems That Require Quick Start Stop.

This Coupling Transmits A Torque Of 16~16000N · M, With A Permissible Speed Of 8000~950r/min (depending On The Model), And Is Suitable For Motors, Reducers, Lifting Machinery, Conveyors, And Other Equipment. The Advantage Lies In Its Compact Structure, And The Integrated Design Of The Brake Wheel And Coupling Saves Space; The Replacement Of The Elastic Sleeve Does Not Require Disassembly Of The Brake Components, Making Maintenance Convenient. However, The Elastic Sleeve Is Greatly Affected By Temperature (-30 ℃~60 ℃), And The Brake Wheel Needs To Be Regularly Inspected For Wear (allowable Wear Amount ≤ 2mm).

When Selecting, It Is Necessary To Match The Shaft Diameter, Torque, And Braking Frequency. The Half Coupling Should Be Made Of 45 Steel Or Cast Iron, And The Elastic Sleeve Should Be Made Of Rubber (high Elasticity) Or Polyurethane (oil Resistant) According To The Working Conditions. Installation Needs To Ensure Alignment Accuracy And Avoid Elastic Sleeve Bias Load. The Braking System Needs To Be Regularly Debugged To Ensure Reliability.